19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

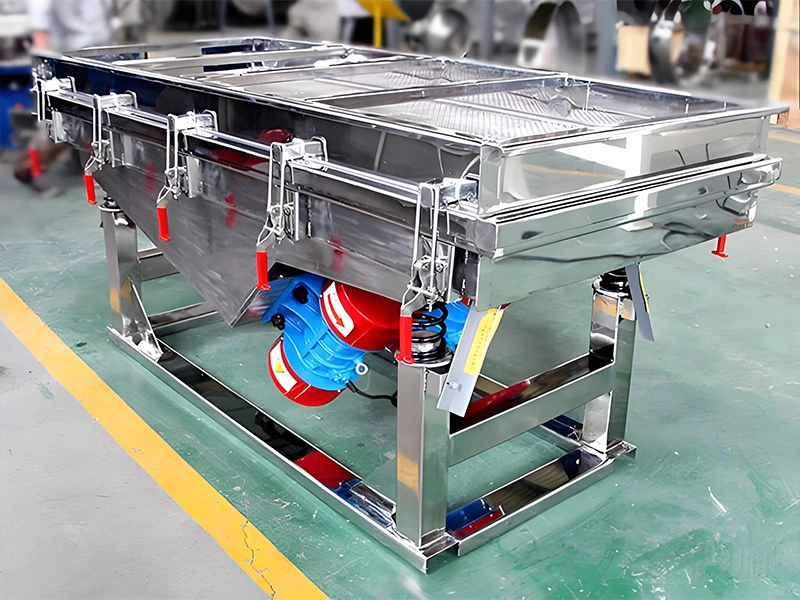

Linear Screen

● Reliability: The vibrating part of the linear vibrating screen is made of high-strength and high-wear-resistant materials, and has the characteristics of long service life and high reliability.

● Flexibility: The linear vibrating screen can be flexibly configured according to different needs, such as adjusting the vibration frequency, amplitude and other parameters to meet various production needs.

● Safety: The vibrating part of the linear vibrating screen and the part in contact with the material adopt special treatments such as anti-wear and anti-corrosion to avoid safety accidents caused by wear.

● Environmental protection: The screening operation of the linear vibrating screen will not produce dust, noise and other pollution, which is conducive to improving the working environment and protecting the environment

Product Description

Linear vibrating screen is a kind of screening and grading screen widely used in mining, coal, electricity, chemical, building materials, food, medicine and other industries. The materials are graded and screened according to the particle size. Its vibration mode is linear vibration, mainly composed of screen box, screen frame, screen, vibration motor, shock-absorbing spring, etc.

Important note: Equipment selection is a relatively important link. Please provide detailed information about the materials and process arrangements as much as possible so that our professionals can provide you with high-quality technical services.

Working Principle

The working principle of the linear vibrating screen is based on a single-degree-of-freedom linear vibration system. The screen box is driven by two vibration motors to generate linear vibration. When the vibration motors rotate in the same direction at the same time, the linear vibration generated causes the material in the screen box to move forward on the screen surface. Particles smaller than the screen hole will leak through the screen hole, while particles larger than the screen hole will remain on the screen surface, thereby achieving screening operations. When the vibration motors rotate in the opposite direction, the linear vibration generated causes the material in the screen box to move backward on the screen surface, so as to remove debris on the screen surface.

Key Parameters

|

Model |

Screen size(mm) |

Material particle size(mm) |

Screen surface inclination(°) |

Amplitude(mm) |

Layers(s) |

Power(kW) |

|

SZF516 |

500×1600 |

0.075~20 |

0~7 |

5~8 |

1~5 |

2×(0.08~0.4) |

|

SZF520 |

500×2000 |

2×(0.4~0.75) |

||||

|

SZF525 |

500×2500 |

2×(0.75~1.1) |

||||

|

SZF530 |

500×3000 |

2×(1.1~1.5) |

||||

|

SZF535 |

500×3500 |

2×(1.1~1.5) |

||||

|

SZF1020 |

1000×2000 |

2×(0.75~1.1) |

||||

|

SZF1025 |

1000×2500 |

2×(1.1~1.5) |

||||

|

SZF1030 |

1000×3000 |

2×(1.5~2.2) |

||||

|

SZF1035 |

1000×3500 |

2×2.2 |

||||

|

SZF1040 |

1000×4000 |

2×(2.2~3.0) |

||||

|

SZF1225 |

1200×2500 |

2×(1.5~2.2) |

||||

|

SZF1230 |

585×3000×2 |

2×(2.2~3.0) |

||||

|

SZF1235 |

585×3500×2 |

2×(2.2~3.0) |

||||

|

SZF1535 |

735×3500×2 |

2×(2.2~3.0) |

||||

|

SZF1540 |

735×4000×2 |

2×(3.0~4.0) |

After 19 years of accumulation and exploration, our team will contribute to the mixed industry with professionalism and ability. We believe that anything is possible through cooperation and enthusiastic service to customers.