19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

Professional Bucket Elevator Conveyor Company

Product details of the bucket elevator conveyor

Product Description

CSPMAC bucket elevator conveyor is carefully and reasonably designed by a group of highly-qualified and experienced designers. It offers infinite possibilities and meets numerous needs. CSPMAC has built a complete quality assurance system and has got bucket elevator conveyor certificate of quality control system.

Product Description

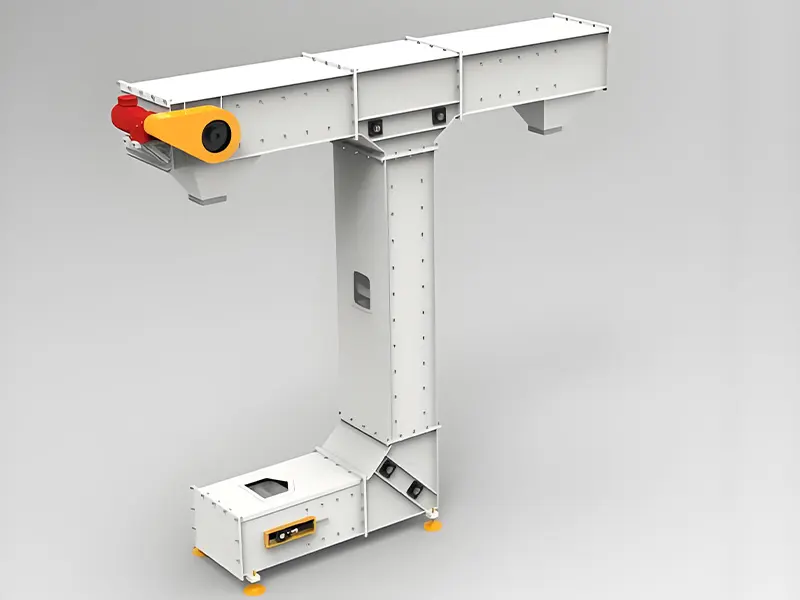

The Z-type bucket elevator integrates vertical lifting and horizontal conveying through a "Z"-shaped path, and is used to convey powders, particles, and sticky materials. A single device can replace the traditional "vertical elevator + belt conveyor" combination, and is particularly suitable for space-constrained factories and multi-floor production line layouts. It uses a shallow bucket hopper and uniform conveying technology to prevent granular materials from breaking due to collision or friction (breakage rate <0.5%), and is especially suitable for industries such as food and chemicals that have high requirements for particle integrity. It can unload at a single point or multiple points.

The hopper material can be selected from carbon steel, stainless steel or plastic according to the conveying material, and the casing can be made of carbon steel, galvanized sheet or stainless steel frame. The Z-type bucket elevator has a compact structure, small footprint, large conveying angle, and can convey materials vertically or obliquely. Good sealing, effectively reducing dust flying, and meeting environmental protection requirements. Smooth operation and low noise are conducive to improving the comfort of the production environment.

Important note: Equipment selection is a relatively important link. Please provide detailed information about the materials and process arrangements as much as possible so that our professionals can provide you with high-quality technical services.

Working Principle

When the Z-type bucket elevator is working, the reduction motor drives the two sprockets to move synchronously through the bearings, so that the two chains meshing with it move synchronously on the closed track. When the material is transported to the feeder, it slides into the horizontal forward hopper. Since the material slides into the hopper and is not forcibly scraped, the material will not be broken. The synchronous movement of the two chains makes the bucket between the two chains move continuously on its closed track. Under the action of the bucket tipping device, the bucket flips, and the material in the bucket falls from the elevator discharge port into the temporary storage hopper of the matching equipment.

The Z-type bucket elevator is mainly composed of a shell, a traction member (conveyor chain), a bucket, a driving wheel (head wheel), a redirecting wheel (tail wheel), a tensioning device, a guide device, a feeding port (inlet) and a discharging port (outlet).

Key Parameters

|

Model |

Elevating capacity |

Bucket volume(L) |

Operation speed |

Elevating height |

Horizontal length |

Motor power (KW) |

|

|

Light model |

HYZD-1L |

3 |

1 |

9-11m/min |

≤10m |

≤10m |

0.75-1.5 |

|

HYZD-1.8L |

5.5 |

1.8 |

9-11m/min |

≤10m |

≤10m |

0.75-3 |

|

|

HYZD-1.8L(>) |

4.3 |

1.8 |

9-11m/min |

≤10m |

≤10m |

1.5-3 |

|

|

HYZD-3.8L |

11 |

3.8 |

9-11m/min |

≤10m |

≤10m |

1.5-3 |

|

|

HYZD-3.8L(>) |

8 |

3.8 |

9-11m/min |

≤10m |

≤10m |

1.5-3 |

|

|

HYZD-4.8L |

14 |

4.8 |

9-11m/min |

≤10m |

≤10m |

1.5-4 |

|

|

HYZD-5.8L |

18 |

5.8 |

9-11m/min |

≤15m |

≤15m |

1.5-5.5 |

|

|

Heavy model |

HYZD-2L |

6 |

2 |

9-11m/min |

≤50m |

≤100m |

0.55-11 |

|

HYZD-3L |

8 |

3 |

9-11m/min |

≤50m |

≤100m |

0.55-11 |

|

|

HYZD-5L |

10 |

5 |

9-11m/min |

≤50m |

≤100m |

0.55-11 |

|

|

HYZD-7L |

12 |

7 |

9-11m/min |

≤50m |

≤100m |

0.55-11 |

|

|

HYZD-10L |

18 |

10 |

9-11m/min |

≤50m |

≤100m |

0.55-11 |

|

|

HYZD-13L |

23 |

13 |

9-11m/min |

≤50m |

≤100m |

0.55-11 |

|

|

HYZD-20L |

28 |

20 |

9-11m/min |

≤50m |

≤100m |

0.55-11 |

|

|

HYZD-30L |

35 |

30 |

9-11m/min |

≤50m |

≤100m |

0.55-11 |

|

|

HYZD-50L |

50 |

50 |

9-11m/min |

≤50m |

≤100m |

0.55-11 |

|

Solution Summary

product case

Company Feature

• Our company values the needs and complaints of consumers. We seek development in demand and solve problems in complaints. Moreover, we continuously take innovation and improvement, and strive to create more and better services for consumers.

• In recent years, CSP runs a relatively complete sales system and actively explores new sales markets, which leads to the annual increment of domestic market share.

• CSP has an elite team with high cohesiveness and technical skills, which provides a strong guarantee for corporate development.

We have ample inventory and discounts for large purchases. Welcome to contact us!