19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

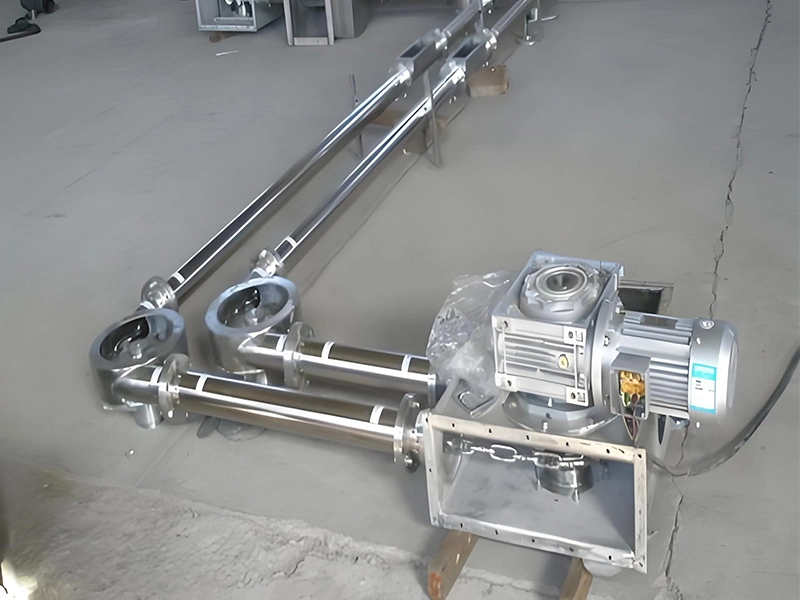

Pipe chain conveyor

● Compact structure and flexible layout: It supports horizontal, vertical, inclined and other installation methods to adapt to different production environment requirements and reduce space occupation.

● Stable conveying: The chain pushes the material to form a stable material flow, with low energy consumption and large conveying capacity, suitable for long distance and high load scenarios.

● Low material breakage rate: The material is smoothly conveyed along the pipeline with small internal movement, suitable for fragile or high-value materials.

● Wide range of applications: It can convey powder, granular, small block and other bulk materials, suitable for the conveying of various forms of materials.

● Convenient maintenance: The transmission components are precisely matched, with removable top and side panels, which is convenient for the assembly and maintenance of parts.

● High degree of automation: It supports multi-point feeding and discharging, and is easy to realize automated production processes.

Product Description

The pipe chain conveyor is an efficient and flexible material conveying equipment used for continuous conveying of bulk materials such as powder, small particles and small blocks. It can be conveyed in a combination of horizontal, inclined and vertical modes. Its application areas are very wide: mining, chemical, food, feed, electricity, metallurgy, building materials and many other industries. Whether it is a harsh environment of high temperature and high pressure, or precise and strict process requirements, the pipe chain conveyor can provide stable and efficient material conveying solutions for all walks of life with its excellent performance and reliability.

Important note: Equipment selection is a relatively important link. Please provide detailed information about the materials and process arrangements as much as possible so that our professionals can provide you with high-quality technical services.

Working Principle

In a closed pipeline, the chain is used as a transmission component to drive the material to move along the pipeline. When conveying horizontally, the material particles are thrust by the chain in the direction of movement. When the internal friction between material layers is greater than the external friction between the material and the pipe wall, the material moves forward with the chain to form a stable material flow; when conveying vertically, the material particles in the pipe are pushed upward by the chain, because the lower feeding prevents the upper material from sliding down, which generates lateral side pressure, thereby enhancing the internal friction of the material. When the internal friction between the materials is greater than the external friction between the materials and the inner wall of the pipe and the weight of the materials, the materials are conveyed upward with the chain to form a continuous material flow.

Key Parameters

|

Model |

Chain tube diameter(mm) |

Capacity(ton/hour) |

Conveying distance(m) |

Power(KW) |

|

TC-50 |

Dn50 |

0.5~1.5 |

0~30 |

0.18~2.2 |

|

TC-80 |

Dn80 |

1~3 |

0~30 |

0.18~3 |

|

TC-100 |

Dn100 |

2~7 |

0~30 |

0.55~4 |

|

TC-125 |

DN125 |

3~10 |

0~30 |

1.1~5.5 |

|

TC-150 |

DN150 |

8~25 |

0~30 |

2.2~7.5 |

|

TC-200 |

DN200 |

15~50 |

0~30 |

3~15 |

|

TC-250 |

Dn250 |

30~75 |

0~30 |

5.5~18.5 |

|

TC-300 |

Dn300 |

60~120 |

0~30 |

7.5~22 |

Solution Summary

product case

After 19 years of accumulation and exploration, our team will contribute to the mixed industry with professionalism and ability. We believe that anything is possible through cooperation and enthusiastic service to customers.