19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

CSPMAC Pharmaceutical Powder Mixer Pharmaceutical Powder Mixer Manufacturer

Product Description

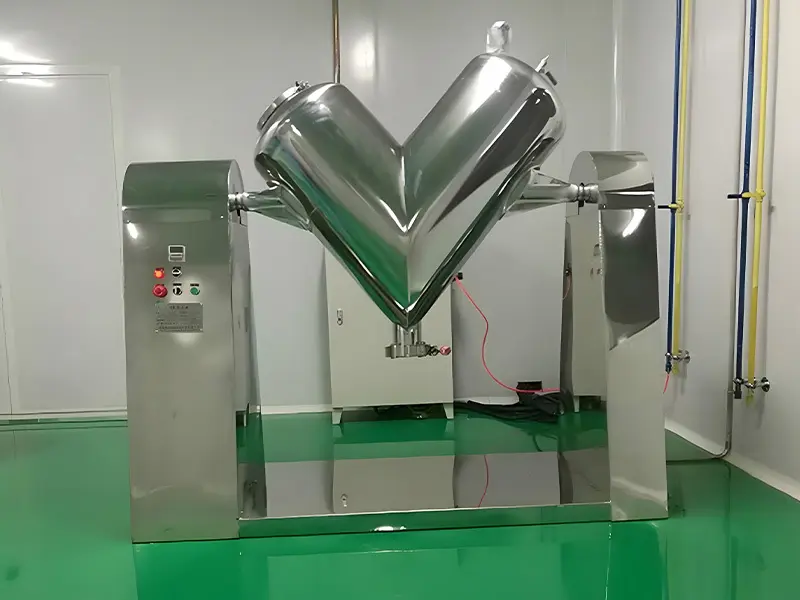

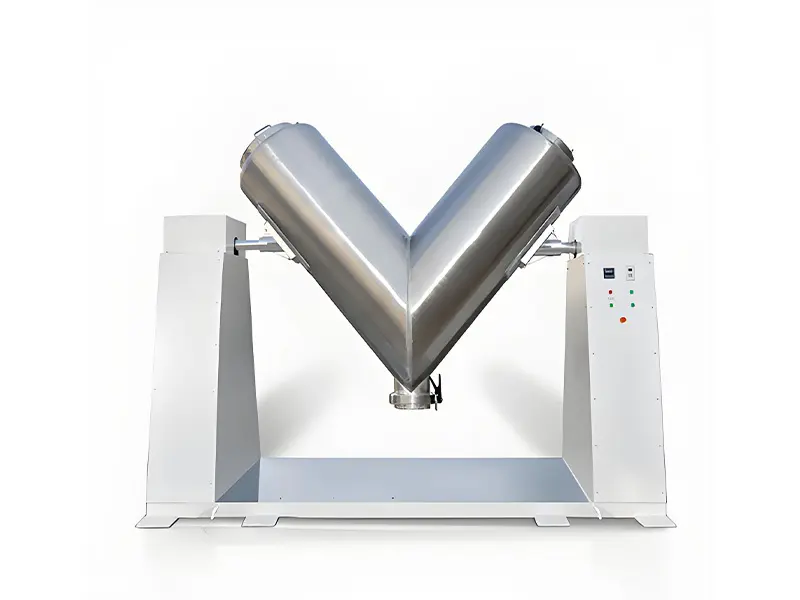

It is mainly used for uniform mixing of powdery and granular materials in the pharmaceutical, chemical, electronic, and food industries.

The V-type mixer is a V-shaped container welded from two cylinders, and the shape of the container is asymmetric with the axis. Due to the rotational motion, the powder particles in the inclined cylinder are repeatedly split and combined alternately, and the material is randomly transferred from one V-shaped area to another V-shaped area. At the same time, the powder particles slide, the space overlaps many times, and the particles are distributed on the newly generated surface. Therefore, shear and diffusion movements are repeated to achieve the purpose of mixing.

Important note: Equipment selection is a relatively important link. Please provide detailed information about the materials and process arrangements as much as possible so that our professionals can provide you with high-quality technical services.

Working Principle

This machine is mainly composed of a mixing barrel, a frame, a transmission system, an electrical system, etc. It uses two asymmetric barrels and adopts gravity mixing. The materials are continuously gathered and dispersed in the barrel. Generally, after about 15 minutes of mixing, two or more powdery and granular materials are fully mixed and evenly mixed. It is especially suitable for mixing two or more materials with large differences in specific gravity, and the mixing uniformity is more than 99%.

Discharge Port Configuration and Sealing Solutions

To meet diverse process layout requirements, the discharge port of the dual-axis gravity-free mixer can be equipped with either a spherical powder valve or a plum-blossom staggered valve:

|

Spherical Powder Valve |

Features a protruding spherical surface that conforms to the curved base of the mixing chamber, minimizing dead zones and residue. Enables a large-diameter discharge opening for efficient material flow. Provides excellent sealing performance for powders, liquids, and even under vacuum conditions. |

|

|

Plum-Blossom Staggered Valve |

Designed for simplicity and precise control over discharge speed. Can be combined with a long spiral bottom support to stabilize material flow. Ideal for applications requiring adjustable discharge rates. |

|

|

Valve Actuation Options |

Manual, Pneumatic, Electric. |

|

|

Sealing Systems |

Standard Packing Seal ,Skeleton Seal, Mechanical Seal. |

|

Features

The mixer is customizable based on material, industry, and process requirements:

- Material Options: Carbon steel, manganese steel, stainless steel (ideal for sanitary or corrosive environments), or other specialized steel alloys.

- Internal Functional Coatings: Anti-corrosion, anti-adhesion, isolation, or wear-resistant coatings/protective layers can be applied to critical areas.

- Stainless Steel Surface Finishes:

- Mechanical Treatments: Sandblasted (matte texture), brushed (linear grain), polished (smooth finish), or mirror-finished (high-gloss).

Customizable Openings

Depending on operational requirements, the mixer's top openings can be configured with:

Functional Ports: Access hatches, cleanout doors, feed inlets, vents, or dust extraction ports.

Opening Styles:

● Flanged Standard Ports – For secure, leak-proof connections.

● Quick-Open Cover Doors – Hinged or removable covers for rapid access.

● Full-Opening Chamber Cover – Entire top section opens for unrestricted internal access and cleaning.

Customizable Components for Diverse Industry and Process Requirements

Can be equipped with a variety of components

|

Specifications |

Effective volume |

Maximum batch output |

Speed |

Power |

Size(mm) |

Weight(kg) |

|

DLZ-0.3 |

0.18 |

200 |

2/68 |

3 |

1730×980×980 |

500 |

|

DLZ-0.5 |

0.18 |

200 |

2/68 |

3 |

2000×1140×1140 |

600 |

|

DLZ-1 |

0.18 |

200 |

1.8/57 |

4 |

2700×1460×1460 |

1200 |

|

DLZ-2 |

0.18 |

200 |

1.8/57 |

5.5 |

3220×1820×1820 |

1500 |

|

DLZ-3 |

0.18 |

200 |

1.8/57 |

7.5 |

3600×2040×2040 |

2300 |

|

DLZ-4 |

0.18 |

200 |

1.8/57 |

11 |

3870×2290×2290 |

2600 |

|

DLZ-5 |

0.18 |

200 |

1.8/57 |

15 |

4200×2460×2460 |

3000 |

|

DLZ-6 |

0.18 |

200 |

1.8/57 |

18.5 |

4420×2560×2560 |

3200 |

|

DLZ-8 |

0.18 |

200 |

1.8/57 |

22 |

4750×2840×2840 |

4000 |

|

DLZ-10 |

0.18 |

200 |

1.8/57 |

37 |

5100×3000×3000 |

5500 |

Product case

Good reasons for working with us

Company Advantages

· CSPMAC pharmaceutical powder mixer is designed by designers with innovative ideas. It is of attractive appearance attracting many customers' eyes and thus has a promising market prospect with its fashionable design.

· The product is well known for its convenience and good durability.

· ZHENGZHOU CSP MACHINERY CO.,LTD. has many years experiences in exporting pharmaceutical powder mixer.

Company Features

· CSPMAC stands out among other pharmaceutical powder mixer manufacturers in the industry.

· The CSPMAC factory has a variety of advanced professional production equipment and testing equipment.

· ZHENGZHOU CSP MACHINERY CO.,LTD. will do our utmost to meet our customers' satisfaction. Please contact us!

Application of the Product

The pharmaceutical powder mixer produced by CSP is very popular in the market and is widely used in industry.

With the concept of 'customers first, services first', CSP always focuses on customers. And we try our best to meet their needs, so as to provide the best solutions.