19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

CSPMAC Powder Mixing Equipment Quality Assurance

Product details of the powder mixing equipment

Product Information

CSPMAC powder mixing equipment is delicately treated to ensure the perfection of every detail. Its quality can withstand the test of the third party. ZHENGZHOU CSP MACHINERY CO.,LTD. has introduced advanced production and testing equipment for better powder mixing equipment.

Product Description

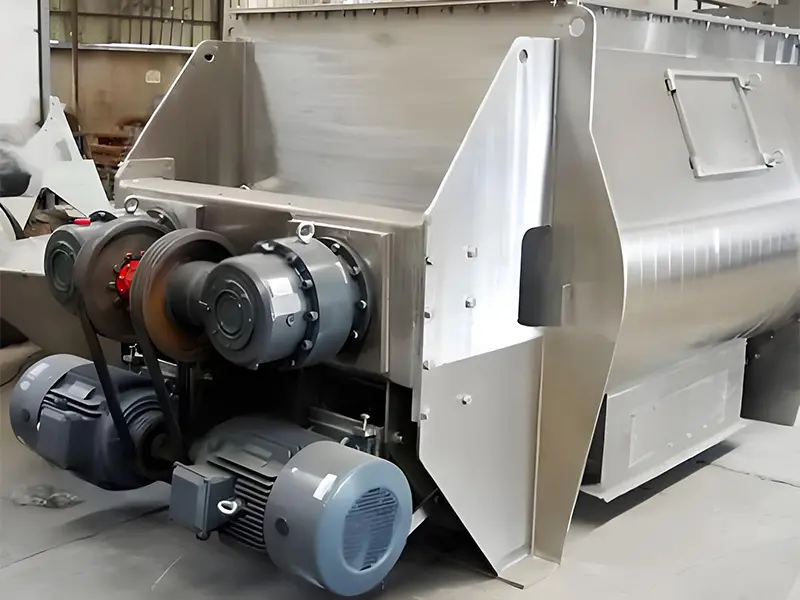

The dual-axis gravity-free mixer is widely used in industries such as chemical, food, pharmaceutical, and feed processing. It is designed for mixing powders, granules, fibers, and other materials. Its key feature lies in the centrifugal force, gravity, and convection generated by the dual-axis rotation, which causes the materials to enter a "gravity-free" state during the mixing process.

This enables rapid and homogeneous blending, even for materials with significant differences in physical properties such as specific gravity, fineness, and flowability. The mixer excels in handling mixtures of materials that vary greatly in these characteristics, ensuring high efficiency and uniform results.

Important note: Equipment selection is a relatively important link. Please provide detailed information about the materials and process arrangements as much as possible so that our professionals can provide you with high-quality technical services.

Working Principle

The gravity-free mixer is equipped with two parallel blade shafts that rotate synchronously in opposite outward directions. Each shaft is fitted with cross-shaped blades. Driven by a synchronized mechanism, the intersecting motion paths of the two cross-bladed shafts overlap and engage in an offset meshing pattern.

When the driving system activates the rapid rotation of the blade shafts, the centrifugal force generated by the spinning blades propels the material upward into the parabolic trajectory within the mixing chamber. At the peak of this parabola (referred to as the "momentary gravity-free state"), the material begins to descend. It is then guided back by the blades, undergoing repeated cycles of circulation and blending within the chamber. Simultaneously, the material is subjected to mixing, shearing, and separation in the overlapping zones between the dual shafts. This dual-action mechanism ensures quick and homogeneous mixing, even for materials with challenging physical disparities.

1.1 Feed valve 2.1 Mixer tank 2.2 Observation door 2.3 Plough share 2.4 Discharge port 2.5 Liquid sprinkler 2.6 Flying cutter group

Support customization

The mixer is customizable based on material, industry, and process requirements:

● Material Options: Carbon steel, manganese steel, stainless steel, or other specialized steel alloys.

● Functional Upgrades: Optional internal coatings or protective layers for anti-corrosion, anti-adhesion, isolation, or wear resistance, tailored to specific operational demands.

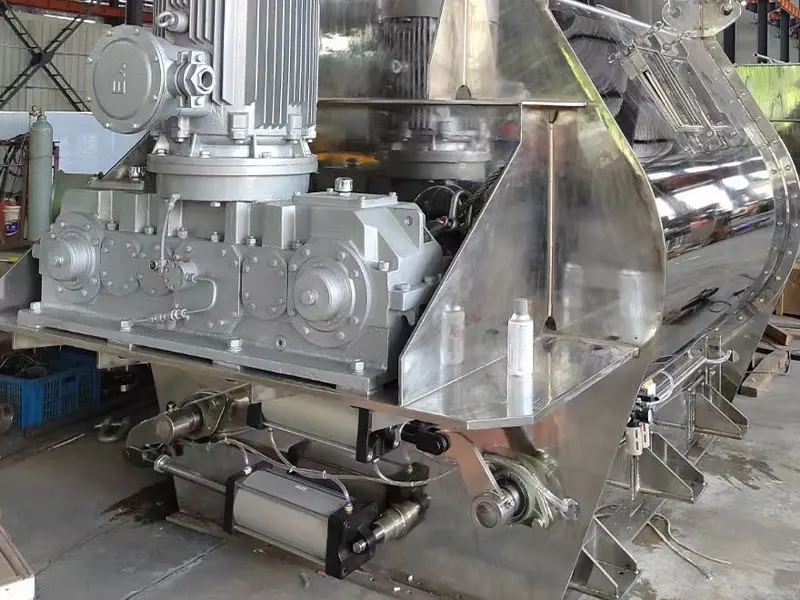

Drive System Configuration

The dual-axis gravity-free mixer is equipped with drive units of varying capacities, power ratings, and output speeds, tailored to material properties, startup methods, and mixing requirements. Due to the intermeshing relationship of the internal blades, the dual-axis drive system must possess synchronization capabilities. Four drive configurations are available for different operational needs:

|

Dual Gearbox Synchronized Combination |

Features two interconnected gearboxes for precise synchronization, ideal for high-torque applications. |

|

|

Single Gearbox Dual-Output Design |

Utilizes a single gearbox with dual output shafts to drive both axes, offering compactness and cost efficiency. |

|

|

Dual Planetary Gear Synchronized System |

Employs planetary gear mechanisms for high-precision synchronization and load distribution, suited for heavy-duty mixing. |

|

|

Bridge Sprocket-Chain Drive |

A chain-and-sprocket linkage system for economical synchronization in moderate-load scenarios. |

|

Internal structure diagram

Mixer Configuration Based on Material Properties

To accommodate diverse material characteristics, the dual-axis gravity-free mixer can be customized with specialized agitators, including:

- Wear-resistant blades for abrasive or high-friction materials.

- PTFE-coated blades for corrosive or chemically reactive substances.

- Serrated blades to enhance shearing and blending efficiency for fibrous or cohesive materials

The double-shaft zero-gravity mixer is usually equipped with a double-door flap, a large-opening discharge valve, and a curved flap valve that fits the curved surface of the cylinder completely, ensuring that there is no dead angle in the mixing and making the mixed materials more uniform.

Customizable Openings

Depending on operational requirements, the mixer's top openings can be configured with:

Functional Ports: Access hatches, cleanout doors, feed inlets, vents, or dust extraction ports.

Opening Styles:

● Flanged Standard Ports – For secure, leak-proof connections.

● Quick-Open Cover Doors – Hinged or removable covers for rapid access.

● Full-Opening Chamber Cover – Entire top section opens for unrestricted internal access and cleaning.

The mixer is designed with three sealing modes to address spindle sealing challenges for materials in granular, powdered, micron-level powdered, liquid, or slurry states:

● Packing Seal

● Combined Pneumatic Seal

● Mechanical Seal

Can be equipped with a variety of components

|

Specifications |

Effective volume |

Maximum batch output |

Speed |

Power |

Size(mm) |

Weight(kg) |

|

JW-2 |

1.2 |

1200 |

51 |

18.5-22 |

2312x2160x1775 |

2500 |

|

JW-3 |

1.8 |

1800 |

36 |

22-30 |

2408x2400x1955 |

2900 |

|

JW-4 |

2.4 |

2400 |

36 |

30-37 |

2822x2546x2015 |

3600 |

|

JW-6 |

3.6 |

3600 |

29 |

37-45 |

3075x2980x2235 |

5600 |

|

JW-8 |

4.8 |

4800 |

29 |

45-55 |

3278x3426x2425 |

7100 |

|

JW-10 |

6 |

6000 |

29 |

55-75 |

3538x3645x2615 |

8000 |

Product case

Good reasons for working with us

Company Feature

• At present, CSP has an excellent work team who is pragmatic, innovative, strict and diligent. One glorious chapter after another is written based on our team members' wisdom and ability.

• CSP's geographic location is superior with multiple traffic lines. This provides convenience for the outward transportation and guarantees the stable supply of Mixed production line,Packaging and palletizing production line.

• Our company strives to create a broad market future, so we open up domestic and international markets. Our products are sold well in China and exported to some countries and regions in Europe, America, Africa and Southeast Asia.

• Since the inception, our company has always been adhering to the service purpose of 'integrity-based, service-oriented'. In order to return our customers' love and support, we provide high-quality products and first-class service.

We only produce high-quality products. Welcome customers to contact customer service staff for consultation!