19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

CSPMAC Powder Vacuum Transfer System Solution Provider

Company Advantages

· The raw materials of CSPMAC powder vacuum transfer system are carefully selected from our reliable suppliers. These quality materials meet with customer's requirements and strict regulatory requirements.

· Theproduct is known for good durability and having a longer functional life.

· The product reaches the requirements of the customers and is popular among customers.

Product Description

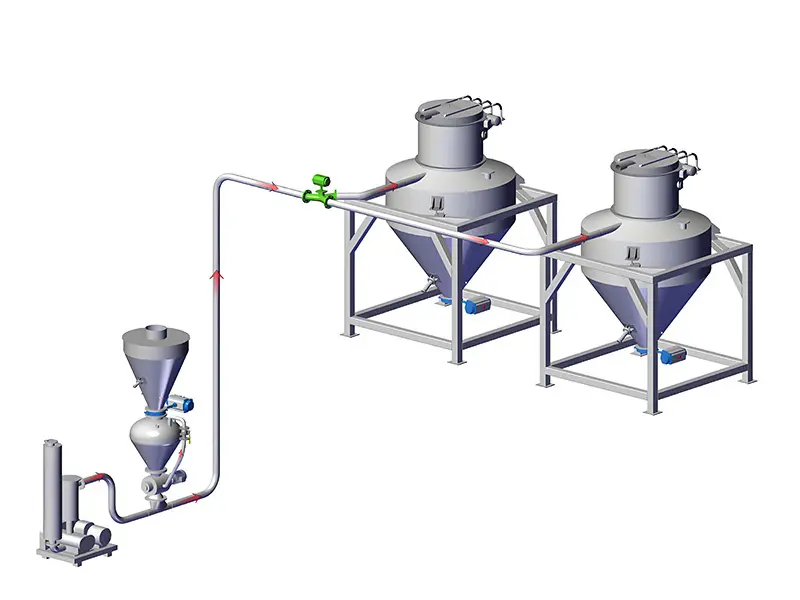

Pneumatic conveying systems utilize airflow energy to transport granular/powder materials through sealed pipelines. This comprehensive technology integrates fluid dynamics, materials science, automation, and manufacturing, offering high efficiency, compact footprint, and eco-friendly operation. Suitable for horizontal, vertical, or inclined transportation, it can simultaneously perform heating, cooling, drying, and particle classification. Compared with mechanical conveying, it consumes more energy with potential particle degradation and equipment wear. Not recommended for moist, adhesive, or static-prone material.

Working Principle

Material transportation is achieved through high-speed airflow carrying suspended particles. Two primary types:

Positive Pressure Dense Phase Pneumatic Conveying System

Category: Positive Pressure Pneumatic Conveying

Product Highlights: High automation level, high material-to-air ratio, low flow velocity, minimal pipeline wear, enclosed and pollution-free transportation, flexible pipeline layout, no occupancy of factory floor space.

Applications: Food, chemical, rubber/plastics, lithium battery, new energy industries.

Basic Principle:The positive pressure dense phase conveying system uses compressed air as the power source to transport materials. It employs forced pneumatic conveying, relying on a sealed pressure vessel (sender tank) as the feeder.

The air source pressure typically ranges from 0.5 MPa to 0.7 MPa, with an operating pressure of 0.3–0.5 MPa. The sender tank operates intermittently, enabling transportation distances exceeding 1,000 meters. Materials are conveyed in pipelines at low speeds, in dune-like, fluidized, or agglomerated states, known as positive pressure dense phase conveying.

Key Parameters

|

Positive Pressure Dense Phase Dynamic Conveying |

|

|

Air velocity |

8–15 m/s |

|

Capacity |

3–50 t/h |

|

Distance |

Up to 100–1,000 m |

|

Air source |

Roots blower, air compressor |

|

Positive Pressure Dense Phase Plug Conveying |

|

|

Air velocity |

4–12 m/s |

|

Capacity |

2–20 t/h |

|

Distance |

Up to 50–200 m |

|

Air source |

High-pressure air compressor |

|

Positive Pressure Dilute Phase Pneumatic Conveying System |

|

|

Category |

Positive Pressure Pneumatic Conveying |

|

Product Highlights |

Long conveying distance, supports one-to-multiple points delivery, and provides partial drying during transportation. |

key Features

- Low flow velocity but high conveying capacity, with minimal impact on material quality.

- High system pressure and low air consumption.

- Automated control system with high requirements for electrical components.

- Supports multi-point feeding and discharging.

- Reduced wear on pipelines and materials due to low conveying velocity.

- Sender tank (or silo pump) is a pressure vessel and a mandatory certified equipment.

- Air source typically uses screw air compressors with required post-processing equipment.

- High reliability and low maintenance, but demands skilled operators.

- Small air volume simplifies material-air separation.

- High working pressure enables long-distance conveying; boosters allow ultra-long distances.

Basic Principle

This system uses Roots blowers or Roots air pumps as the power source. Materials are transported at high speeds in a dispersed, suspended state within pipelines, driven by air kinetic energy. The conveying pressure ranges from several kPa to hundreds of kPa.

System Features

- High-speed material transport (8–25 m/s) using gas dynamic pressure; pressure decreases along the pipeline.

- Continuous conveying with stable flow state, pressure, speed, and material-to-air ratio; easy maintenance.

- Enables multi-point feeding and discharging.

- Simplified closed-loop control without additional gas buffering equipment.

- Shorter conveying distance compared to positive pressure dense phase but longer than negative pressure dilute phase.

- High outlet air temperature from Roots blowers.

- Requires tightly sealed rotary feed valves to prevent gas leakage.

Key Parameters

|

Pressure |

0.02–0.08 MPa (varies with material density, distance, height). |

|

Material-to-air ratio |

1–25. |

|

Conveying speed |

Initial 10 m/s to terminal 20 m/s. |

|

Distance |

Height ≤20 m, horizontal ≤200 m. |

|

Power source |

Roots blower, centrifugal fan. |

Negative pressure dilute phase pneumatic conveying system

Category: Negative pressure pneumatic conveying

Product highlights:

1. The sealing requirements for pipelines and other sealing parts are lower than positive pressure conveying, and there is no risk of powder spraying.

2. It can play a certain role in cooling materials during material conveying.

3. Suitable for multi-point to one-point conveying.

Basic principle:

System Features

Key Parameters

|

Conveying pressure |

-49Kpa~-69Kpa (determined by material specific gravity, distance and height); |

|

Material-gas ratio |

1~25; |

|

Conveying speed |

generally, about 10-20m/s; |

|

Conveying distance |

generally, height ≤20 meters, horizontal ≤80 meters; |

|

Power source |

Roots blower, vortex blower, claw vacuum pump. |

Negative pressure continuous pneumatic conveying system

Category: Negative pressure pneumatic conveying

Product highlights: Continuous loading and unloading improves loading efficiency and saves equipment costs.

Basic principle:

System Features

Key Parameters

|

1 |

The system uses Roots blower or high-pressure vortex blower as the power source, and the working pressure is generally ≤-65kpa; |

|

2 |

Negative pressure continuous conveying is to replace the pneumatic butterfly valve under the vacuum feeder of the traditional batch feeding with a rotary feeding valve that can feed continuously and has a certain air locking ability; |

|

3 |

After replacing with a rotary feeding valve, a negative pressure continuous conveying method of feeding and unloading at the same time can be realized. |

Company Features

· As a well-known manufacturer for powder vacuum transfer system, ZHENGZHOU CSP MACHINERY CO.,LTD. occupies a large market share.

· The factory is situated in a place where is near to the raw materials suppliers. This guarantees the quality and quantity of raw materials, as well as relatively low sourcing costs. With a production certificate, we are authorized to manufacture and market products freely. Besides, this certificate supports the company entering the powder vacuum transfer system market.

· We take clients' high satisfaction as our ultimate goal. We will honor every one of our commitments and follow up by actively listening to clients' needs and concerns.

Product Details

Next, CSP will present you with the specific details of powder vacuum transfer system.

Product Comparison

The quality of CSP's powder vacuum transfer system is better than the quality of its peer products. It is shown in the following aspects.