19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

Powder Packaging Equipment PRODUCTS Wholesale - CSPMAC

Product details of the powder packaging equipment

Product Overview

The finest quality of raw materials and sophisticated technology used make CSPMAC powder packaging equipment fine in craftsmanship. The product is highly praised for its strong usability and consistent performance. The powder packaging equipment developed and produced by our company can be widely used in various industries and professional fields. ZHENGZHOU CSP MACHINERY CO.,LTD. provides sharp competitive rates to your business.

Product Information

powder packaging equipment has the following advantages over other products in the same category.

Product Description

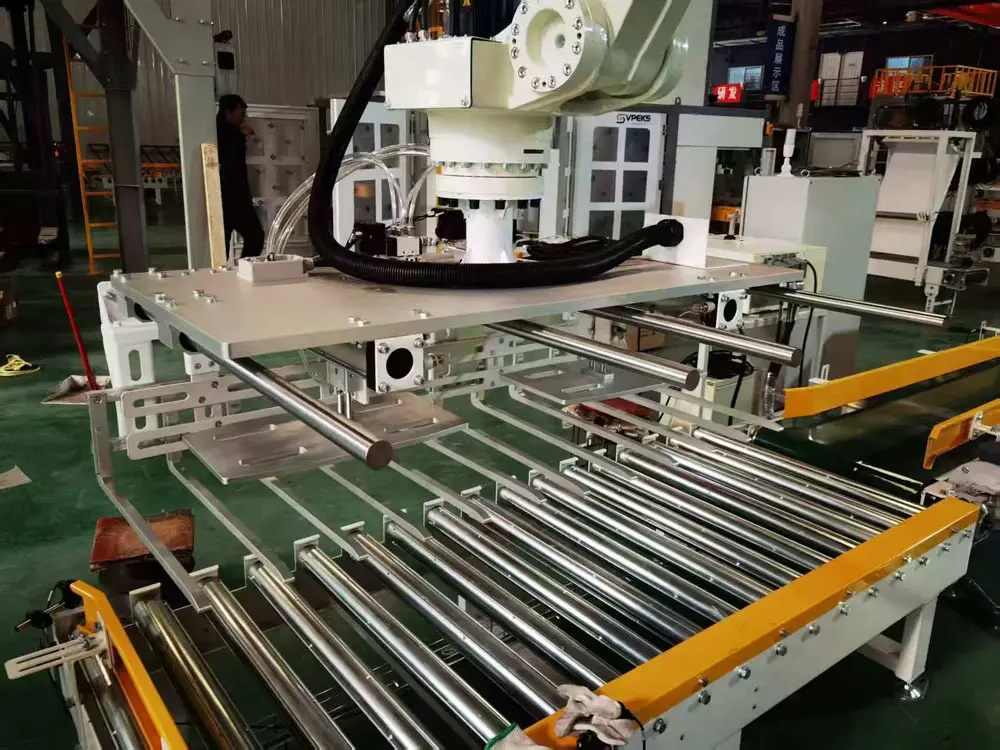

Automated palletizing robots are by far the most efficient way to palletize and depalletize single-piece goods on pallets of any size.

There are several explanations for this:

First, the palletizing operation can be easily robotized because it is a sequence to repeat the same type of operation, which can be easily programmed in the palletizing robot.

Second, if grip and load capacity allow, palletizing robots can be easily reprogrammed and reconfigured not only from one stacking pattern to another, but also from one type of product to another. Palletizing robots are absolutely versatile in this regard.

● Reduce the palletizing time and improve the quality of the whole pallet;

● Automatic palletizing by robots;

● Stable running speed;

● Able to work around the clock;

● Eliminate the negative impact of human factors on the production process.

Working Principle

The operation process of the palletizing robot production line is as follows. The goods to be palletized are transported to the grabbing position by the conveyor, and at same time the empty pallets are transported to the palletizing position by the automatic pallet feeder, and then the palletizing robot grab the goods and stack them on the pallet according to the set quantity and stack type. Today, robotic stacking is applied to a variety of products such as bricklaying, bags, boxes, etc.

The reverse operation of palletizing is depalletizing. In this operation, the robot removes objects from pallets and transfers them to conveyor belts or machines for further processing. Nowadays, the robotization of CNC machine tools is becoming more and more common. The robot takes the workpiece from the pallet, places it in the machine, captures the finished product after processing, takes it from the machine and places it on another pallet.

application areas

To sum up, modeling robots mainly have the following three application areas:

- Placing the product in primary packaging;

- Packing products in corrugated boxes and other containers;

- Stack products on pallets and remove them from pallets.

product case

Company Advantages

ZHENGZHOU CSP MACHINERY CO.,LTD. runs the main business of Mixed production line,Packaging and palletizing production line. The company is located in zheng zhou. Insisting on the business philosophy of 'serving customers wholeheartedly', our company sincerely provides more and better products and services. If you want to know more details of our products, please contact us. We are looking forward to cooperating with you!