19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

Powder Packaging Machine Conveying & Feeding Systems Wholesale - CSPMAC

Product details of the powder packaging machine

Product Introduction

CSPMAC powder packaging machine is well-designed by the R&D team with a deep consideration. The product is known for its less maintenance and outstanding performance. This product is basically known with a wide range of applications.

Product Description

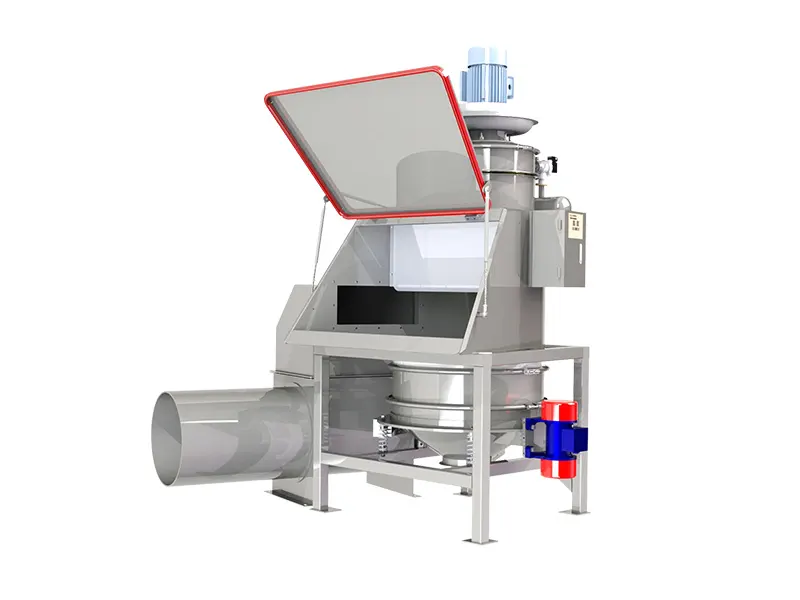

This equipment is suitable for unpacking, placing, screening and unloading of small and medium-sized bag materials in the food, pharmaceutical, chemical and metallurgical industries. It is especially suitable for manual feeding and pre-screening of powder materials. The dust collecting fan can prevent the dust from flying everywhere during unpacking. When the small bag materials need to be unpacked and poured into the next process, they only need to be unpacked manually and put into the system. The dust generated during feeding is collected by the dust collecting fan. The material can intercept large pieces of material and foreign matter through the vibrating screen (safety screen), so as to ensure that the finished products (qualified materials) that meet the requirements enter the next process.

Important note: Equipment selection is a relatively important link. Please provide detailed information about the materials and process arrangements as much as possible so that our professionals can provide you with high-quality technical services.

Working Principle

Key Parameters

|

Model |

Screen area |

Power(kW) |

Rotation speed(r·p·m) |

Dynamic load |

Static load |

Exciting force (kN) |

Flow |

Wind pressure |

|

WT-800 |

0.42 |

2×0.18 |

1460 |

800N |

1500N |

2.5×2 |

1550-997 |

1217-1641 |

|

WT-1000 |

0.64 |

2×0.25 |

1460 |

500N |

2500N |

5×2 |

1550-997 |

1217-1641 |

product case

Company Advantage

• Our company's geographical position is excellent. Therefore, we are provided with good natural conditions, developed communication and convenient transportation.

• CSP's Mixed production line,Packaging and palletizing production line are of good quality and affordable price. They enjoy a high market share in the country. They are also sold to many overseas countries and regions and receive their favor and praise.

• CSP has a high-quality production team and professional inspection personnel to ensure excellent quality of products.

We are responsible for the production of high-quality products, please contact us to order if in need.