19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

Powder Packing Machine Mixing Equipment Wholesale - CSPMAC

Product details of the powder packing machine

Product Introduction

CSPMAC powder packing machine is fabricated using optimum quality raw materials and pioneering technology. The product is promised with high quality and long service life. CSPMAC is professional in manufacturing powder packing machine with distinguished quality.

Product Description

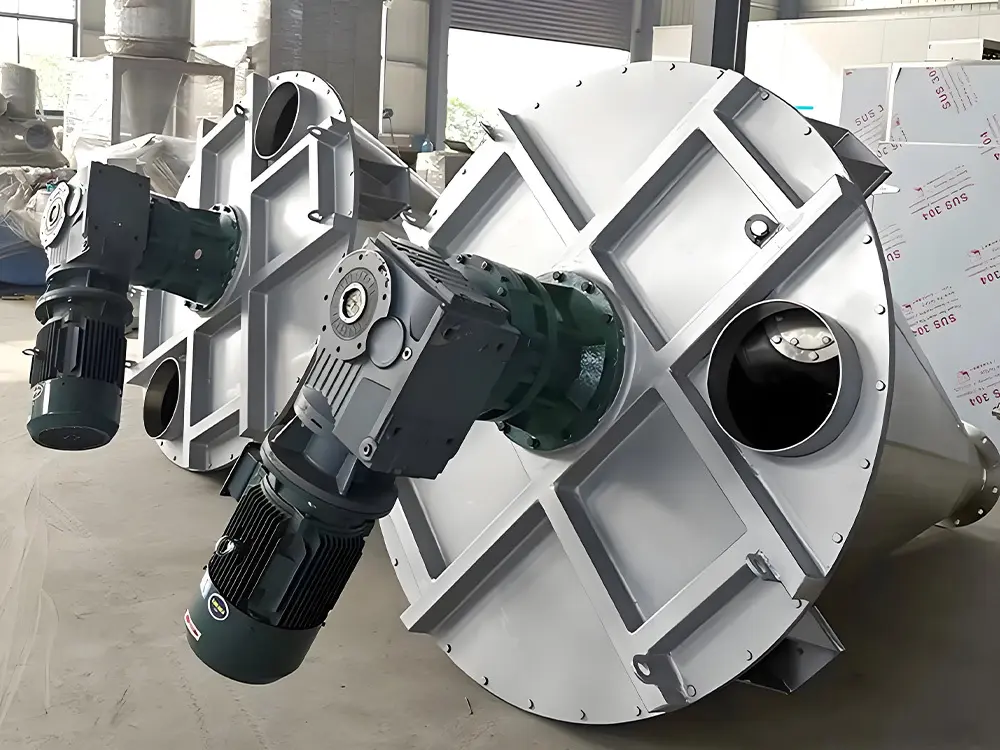

The cone mixer has wide adaptability, will not overheat heat-sensitive materials, will not extrude and grind granular materials, and will not produce stratification and segregation when mixing materials with different specific gravities and particle sizes. It is widely used in the mixing process of powders and powders, particles and particles, powder and liquid in the fields of chemicals, pesticides, dyes, food, battery materials, rare earths, photovoltaics, fertilizers, rubber and plastic materials, etc.

The driving device of the double-helix cone mixer can output two independent sets of output shafts with different speeds at the same time, and the spiral on the cantilever can form a revolution and rotation mode during stirring.

The ribbon cone mixer and the paddle cone mixer adopt a single-output shaft drive, and a sealing isolation device is installed at the output shaft position of the drive group to prevent any leakage pollution.

Important note: Equipment selection is a relatively important link. Please provide detailed information about the materials and process arrangements as much as possible so that our professionals can provide you with high-quality technical services.

Working Principle

The Dual-Spiral Conical Mixer achieves thorough blending through four synergistic forces generated by two asymmetric spirals:

Discharge Port Configuration and Sealing Solutions

To meet diverse process layout requirements, the discharge port of the dual-axis gravity-free mixer can be equipped with either a spherical powder valve or a plum-blossom staggered valve:

|

Spherical Powder Valve |

Features a protruding spherical surface that conforms to the curved base of the mixing chamber, minimizing dead zones and residue. Enables a large-diameter discharge opening for efficient material flow. Provides excellent sealing performance for powders, liquids, and even under vacuum conditions. |

|

|

Plum-Blossom Staggered Valve |

Designed for simplicity and precise control over discharge speed. Can be combined with a long spiral bottom support to stabilize material flow. Ideal for applications requiring adjustable discharge rates. |

|

|

Valve Actuation Options |

Manual, Pneumatic, Electric. |

|

|

Sealing Systems |

Standard Packing Seal ,Skeleton Seal, Mechanical Seal. |

|

Features

Customizable to meet material, industry, and process requirements:

- Material Options: Carbon steel, manganese steel, stainless steel (ideal for sanitary or corrosive environments), or other specialized steel alloys.

- Internal Functional Coatings: Anti-corrosion, anti-adhesion, isolation, or wear-resistant coatings/protective layers can be applied to critical areas.

- Stainless Steel Surface Finishes: Mechanical Treatments: Sandblasted (matte texture), brushed (linear grain), polished (smooth finish), or mirror-finished(high-gloss).

Drive System Configuration

The mixer's drive system is customized with varying power and capacity based on material properties, startup methods, and process requirements.

Dual-Spiral Conical Mixer Features

Equipped with a dedicated dual-output reducer gearbox assembly, custom-built using cycloidal pinwheel, gear, or worm gear mechanisms for precise torque and speed control.

Agitator: Two asymmetric spirals are fixed on a revolving cantilever; Single-axis double-helix blade agitator

Customizable Openings

Depending on operational requirements, the mixer's top openings can be configured with:

Functional Ports: Access hatches, cleanout doors, feed inlets, vents, or dust extraction ports.

Opening Styles:

● Flanged Standard Ports – For secure, leak-proof connections.

● Quick-Open Cover Doors – Hinged or removable covers for rapid access.

● Full-Opening Chamber Cover – Entire top section opens for unrestricted internal access and cleaning.

Customizable Components for Diverse Industry and Process Requirements

The dual-axis gravity-free mixer can be equipped with various add-on components to meet specific industrial and process needs, including:

Process-Specific Configurations: Vacuum or Pressurized Operation: Customized for vacuum or pressurized environments to handle sensitive, reactive, or volatile materials.

Heating/Cooling Systems: Integrated with circulating medium jackets or steam coil jackets for precise temperature control during mixing.

Material-Specific Enhancements: Specialized Coatings: Anti-corrosion, anti-adhesion, or metal-isolating coatings to protect against aggressive, sticky, or reactive materials.

Wear-Resistant Mixing Screws: Screws reinforced with overlay welding of wear-resistant alloys for prolonged service life in abrasive applications.

Liquid Dispersion System: Liquid Spray Module: A pressure-fed spray system (comprising a pressure source, liquid reservoir, and spray nozzles) ensures uniform dispersion of small liquid volumes into bulk materials, enhancing homogeneity and preventing localized clumping.

Thermal Management: Jacketed Designs: Maintain consistent thermal conditions for heat-sensitive or exothermic reactions, ensuring stable mixing performance.

Can be equipped with a variety of components

|

Specifications |

Effective volume |

Maximum batch output |

Speed |

Power |

Size(mm) |

Weight(kg) |

|

DLZ-0.3 |

0.18 |

200 |

2/68 |

3 |

1730×980×980 |

500 |

|

DLZ-0.5 |

0.18 |

200 |

2/68 |

3 |

2000×1140×1140 |

600 |

|

DLZ-1 |

0.18 |

200 |

1.8/57 |

4 |

2700×1460×1460 |

1200 |

|

DLZ-2 |

0.18 |

200 |

1.8/57 |

5.5 |

3220×1820×1820 |

1500 |

|

DLZ-3 |

0.18 |

200 |

1.8/57 |

7.5 |

3600×2040×2040 |

2300 |

|

DLZ-4 |

0.18 |

200 |

1.8/57 |

11 |

3870×2290×2290 |

2600 |

|

DLZ-5 |

0.18 |

200 |

1.8/57 |

15 |

4200×2460×2460 |

3000 |

|

DLZ-6 |

0.18 |

200 |

1.8/57 |

18.5 |

4420×2560×2560 |

3200 |

|

DLZ-8 |

0.18 |

200 |

1.8/57 |

22 |

4750×2840×2840 |

4000 |

|

DLZ-10 |

0.18 |

200 |

1.8/57 |

37 |

5100×3000×3000 |

5500 |

Product case

Good reasons for working with us

Company Feature

• CSP's Mixed production line,Packaging and palletizing production line are sold well in various regions in the country and are favored by many customers for they are safe and eco-friendly. In addition, we strive to promote the products to the world by opening up the foreign market.

• CSP, established in has been developing in the industry for years.

• During the process of production and operation for many years, our company has cultivated an outstanding talents team. They are united and cooperative to work efficiently.

• With a deep understanding of customers' needs and market, our company can provide customers with convenient pre-sales consultation and perfect after-sales service.

Our products are of excellent quality and favorable price, winning a wide recognition. If you want to know more about the products, please contact us!