19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

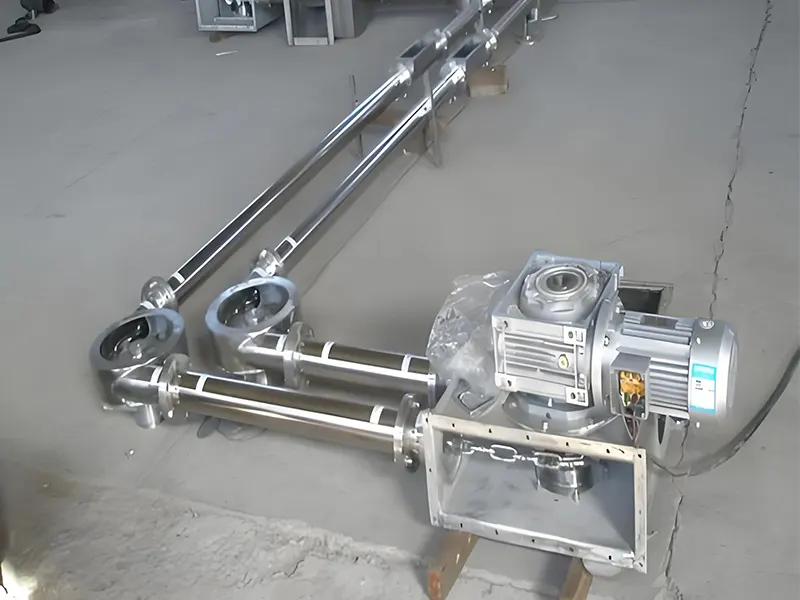

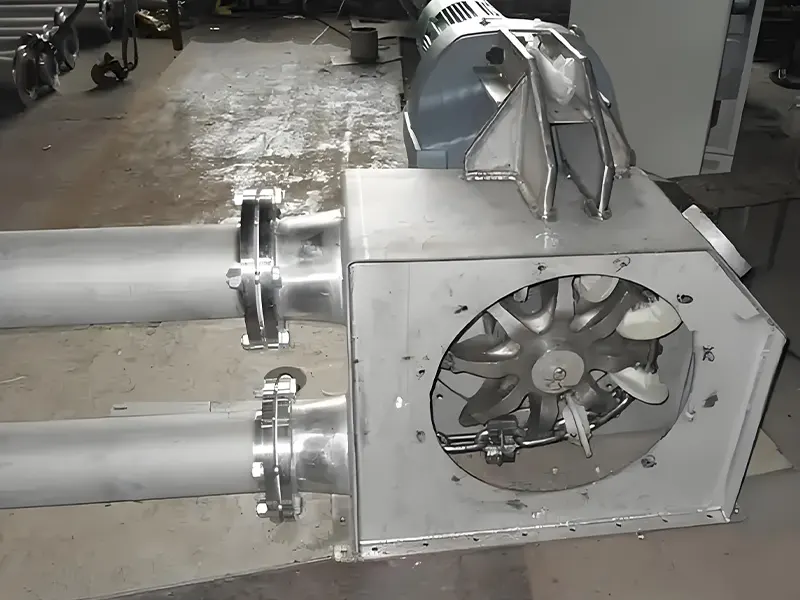

Tubular Drag Chain Conveyor Conveying & Feeding Systems Wholesale - CSPMAC

Product details of the tubular drag chain conveyor

Quick Detail

CSPMAC tubular drag chain conveyor is manufactured from upper material and technique. We meet the quality standards as per the customer demands. The product has won the trust and approval of its customers and is promising in the future application.

Product Introduction

Based on the professionalism of pursuing excellence, we strive for perfection in every detail of the product.

Product Description

The pipe chain conveyor is an efficient and flexible material conveying equipment used for continuous conveying of bulk materials such as powder, small particles and small blocks. It can be conveyed in a combination of horizontal, inclined and vertical modes. Its application areas are very wide: mining, chemical, food, feed, electricity, metallurgy, building materials and many other industries. Whether it is a harsh environment of high temperature and high pressure, or precise and strict process requirements, the pipe chain conveyor can provide stable and efficient material conveying solutions for all walks of life with its excellent performance and reliability.

Important note: Equipment selection is a relatively important link. Please provide detailed information about the materials and process arrangements as much as possible so that our professionals can provide you with high-quality technical services.

Working Principle

In a closed pipeline, the chain is used as a transmission component to drive the material to move along the pipeline. When conveying horizontally, the material particles are thrust by the chain in the direction of movement. When the internal friction between material layers is greater than the external friction between the material and the pipe wall, the material moves forward with the chain to form a stable material flow; when conveying vertically, the material particles in the pipe are pushed upward by the chain, because the lower feeding prevents the upper material from sliding down, which generates lateral side pressure, thereby enhancing the internal friction of the material. When the internal friction between the materials is greater than the external friction between the materials and the inner wall of the pipe and the weight of the materials, the materials are conveyed upward with the chain to form a continuous material flow.

Key Parameters

|

Model |

Chain tube diameter(mm) |

Capacity(ton/hour) |

Conveying distance(m) |

Power(KW) |

|

TC-50 |

Dn50 |

0.5~1.5 |

0~30 |

0.18~2.2 |

|

TC-80 |

Dn80 |

1~3 |

0~30 |

0.18~3 |

|

TC-100 |

Dn100 |

2~7 |

0~30 |

0.55~4 |

|

TC-125 |

DN125 |

3~10 |

0~30 |

1.1~5.5 |

|

TC-150 |

DN150 |

8~25 |

0~30 |

2.2~7.5 |

|

TC-200 |

DN200 |

15~50 |

0~30 |

3~15 |

|

TC-250 |

Dn250 |

30~75 |

0~30 |

5.5~18.5 |

|

TC-300 |

Dn300 |

60~120 |

0~30 |

7.5~22 |

Solution Summary

product case

Company Introduction

ZHENGZHOU CSP MACHINERY CO.,LTD.(CSP) mainly supplies Mixed production line,Packaging and palletizing production line. 企业名称] always adheres to the business philosophy of 'quality wins the market, reputation creates the future' and carries forward the enterprise spirit of 'determined and progressing, developing and innovating'. With the consistent focus on integrated industrialization, we strive to improve our core competitiveness and to become a modern enterprise with a wide brand recognition, great innovation ability, and good economic benefits. CSP has a group of high-quality technical personnel and a highly efficient production team. Besides, we adopt advanced development tools and concepts for product research and development. With a focus on customers, CSP analyzes problems from the perspective of customers. And we provide customers with comprehensive, professional and excellent solutions.

Our products are guaranteed to be quality. Customers with needs are welcomed to contact us for purchase.