19+ years of experience - Comprehensive solutions supplier for mixing and packaging of powder and granular materials.

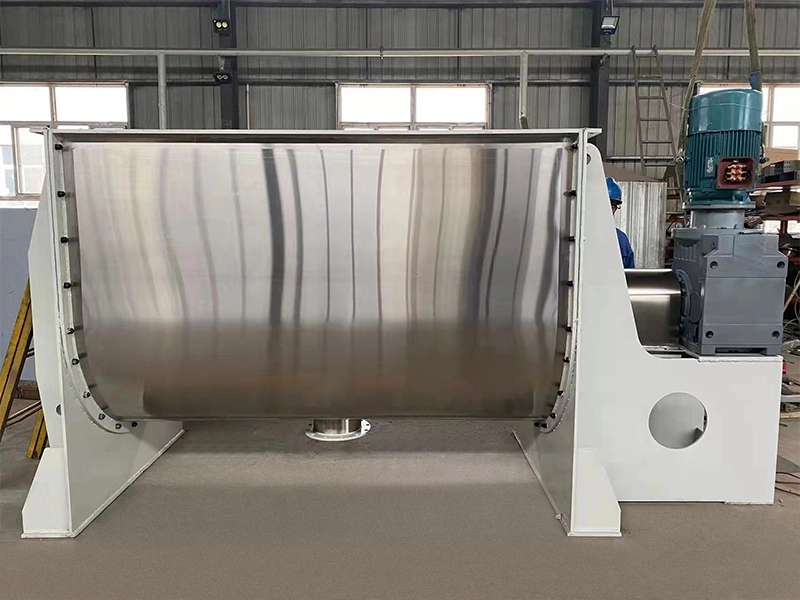

LH horizontal ribbon mixer - powder, slurry, particle blending for industrial use

● Rational Design - Features an easy-to-install and maintain structure, excellent sealing performance to prevent dust pollution, and environmentally friendly operation.

● High Mixing Homogeneity - Counter-rotating inner and outer ribbons ensure thorough radial and axial mixing of materials in the trough without dead zones.

● Efficient & Energy-Saving - High-speed ribbon rotation combined with multidirectional material movement reduces mixing time. Ideal for large batches with substantial single-batch capacity.

● User-Friendly Operation - Automated control system allows precise adjustment of mixing time and speed for simplified operation and maintenance.

Product Description

LH horizontal ribbon mixer is widely used in chemical, pharmaceutical, food, building materials, plastics, pigments, cosmetics, and other fields. It can be used for mixing powders, adding a small amount of liquid to powders, adding liquid to powders and stirring them into a slurry, thickening or diluting the slurry, mixing powders and particles, mixing particles and particles, crushing and mixing agglomerates, cooling or heating, and mixing and other processes.

Important note: Equipment selection is a relatively important link. Please provide detailed information about the materials and process arrangements as much as possible so that our professionals can provide you with high-quality technical services.

Working Principle

The horizontal ribbon mixer consists of a mixing chamber, an agitator, and a drive assembly. A U-shaped tubular or cylindrical chamber houses a dual-layer, counter-rotating ribbon agitator shaft. The outer ribbon, driven by the motor, rotates to push materials from both ends of the chamber toward the center. The inner ribbon transports materials from the center to both ends, creating a continuous counter-current mixing flow. A centrally located discharge port at the bottom of the horizontal chamber ensures residue-free emptying. The outer ribbon's helical structure, aligned with the rotation direction, efficiently guides materials along the chamber walls to the central discharge port, guaranteeing zero dead zones during discharge.

Support customization

The mixer is customizable based on material, industry, and process requirements:

● Material Options: Carbon steel, manganese steel, stainless steel, or other specialized steel alloys.

● Functional Upgrades: Optional internal coatings or protective layers for anti-corrosion, anti-adhesion, isolation, or wear resistance, tailored to specific operational demands.

Drive System Configuration

|

Drive Motor Options |

Common Reducer Types |

Connection Methods |

|

● Standard motors |

● R/K/F series gear reducers |

● Direct coupling (rigid shaft connection) (shock absorption, overload protection) |

|

|

|

|

The mixer can be equipped with different agitator types tailored to material characteristics:

Discharge Port Configurations

The drive system is configured with varying capacities, power ratings, and output speeds based on material properties, starting methods, and mixing requirements.

To meet diverse process requirements, the discharge port can be equipped with a pneumatic curved flap valve.

Seamless Design: When closed, the valve's curved flap perfectly conforms to the chamber's inner contour, eliminating dead zones during mixing and ensuring uniform material homogeneity.

Actuation Options: Manual, pneumatic, or electric drive systems.

Additional Valve Types:

● Spherical Powder Valves

● Roller Valves

● Multi-Blade Staggered Valves

● Powder Butterfly Valves

● Rotary Feed Valves

Customizable Openings

Depending on operational requirements, the mixer's top openings can be configured with:

Functional Ports: Access hatches, cleanout doors, feed inlets, vents, or dust extraction ports.

Opening Styles:

● Flanged Standard Ports – For secure, leak-proof connections.

● Quick-Open Cover Doors – Hinged or removable covers for rapid access.

● Full-Opening Chamber Cover – Entire top section opens for unrestricted internal access and cleaning.

According to different industries and process requirements, the mixer can be equipped with a variety of components:

● Coil Steam Jackets – For uniform temperature control.

● Honeycomb Pressure-Resistant Jackets – Optimized for high-pressure thermal exchange.

● Circulating Medium Jackets – Compatible with heating or cooling fluids.

● Temperature Range: Up to 250°C.

● Spray Nozzle Assembly – Ensures even dispersion of liquids into bulk materials.

● Key Modules: Pressure source, liquid reservoir, and precision spray nozzles.

● In-line Sampling Valves – For real-time quality monitoring.

● High-Speed Chopper Blades – Breaks down agglomerates during mixing.

● Magnetic Separators – Removes ferrous contaminants.

● Temperature Probes & Weighing Systems – Process automation and data tracking.

● Dust Removal/Purification Units – Ensures clean operation in dust-sensitive environments.

Can be equipped with a variety of components

|

Specifications |

Effective volume |

Maximum batch output |

Speed |

Power |

Size(mm) |

Weight(kg) |

|

LH-100 |

0.06 |

60 |

69 |

2.2 |

1400×600×750 |

250 |

|

LH-200 |

0.12 |

120 |

69 |

3.7 |

1600×800×850 |

450 |

|

LH-0.3 |

0.18 |

200 |

62 |

5.5 |

1900×1000×950 |

600 |

|

LH-0.5 |

0.3 |

300 |

62 |

7.5 |

2250×1150×1250 |

900 |

|

LH-1 |

0.6 |

600 |

49 |

11 |

2650×1300×1400 |

1500 |

|

LH-2 |

1.2 |

1200 |

33 |

15 |

3200×1500×1650 |

2500 |

|

LH-3 |

1.8 |

1800 |

33 |

18.5 |

3900×1750×1750 |

3600 |

|

LH-4 |

2.4 |

2500 |

27 |

22 |

4100×1800×1900 |

4200 |

|

LH-5 |

3 |

3000 |

27 |

30 |

4250×1850×2000 |

5100 |

|

LH-6 |

3.6 |

3600 |

27 |

37 |

4750×1900×2200 |

5600 |

|

LH-8 |

4.8 |

4800 |

22 |

45 |

5100×2150×2300 |

6500 |

|

LH-10 |

6 |

6000 |

22 |

55 |

5580×2170×2500 |

7800 |

Solution summary

● 1: Use ton bags of raw materials, crane hoisting, and direct feeding with dust collector;

● 2: Set up a multi-layer platform, manually unpack bags and feed, and use a ton belt packaging machine after mixing and discharging;

● 3: Simple use of mixing equipment, direct feeding and direct discharge, and configure forklift loading and unloading;

● 4: Use a manual feeding platform, spiral lift the materials into the finished product warehouse after mixing, and connect the packaging equipment below;

● 5: Use vacuum feeding method, feed on the ground, and use a ton belt packaging machine after mixing and discharging;

● 6: Multi-stage vacuum feeding and transportation, after mixing and storage, packaging;

● 7: Multi-layer operating table design, freight elevator feeding, feeding, warehousing, mixing, storage, packaging, integrated tower structure;

● 8: Use bucket elevator to feed, mix, store, and package;

● 9: Vacuum feeder feeding, mixing, warehousing, packaging, upper and lower integrated structure;

● 10: Manual feeding, mixing, warehousing, packaging, upper and lower integrated structure.

Product Configuration

The project adopts a dust-free feeding station, which uses vacuum feeding to pneumatically convey the materials into the mixer, and then pneumatically conveys them to the finished product packaging link after being fully mixed.

Good reasons for working with us

After 19 years of accumulation and exploration, our team will contribute to the mixed industry with professionalism and ability. We believe that anything is possible through cooperation and enthusiastic service to customers.